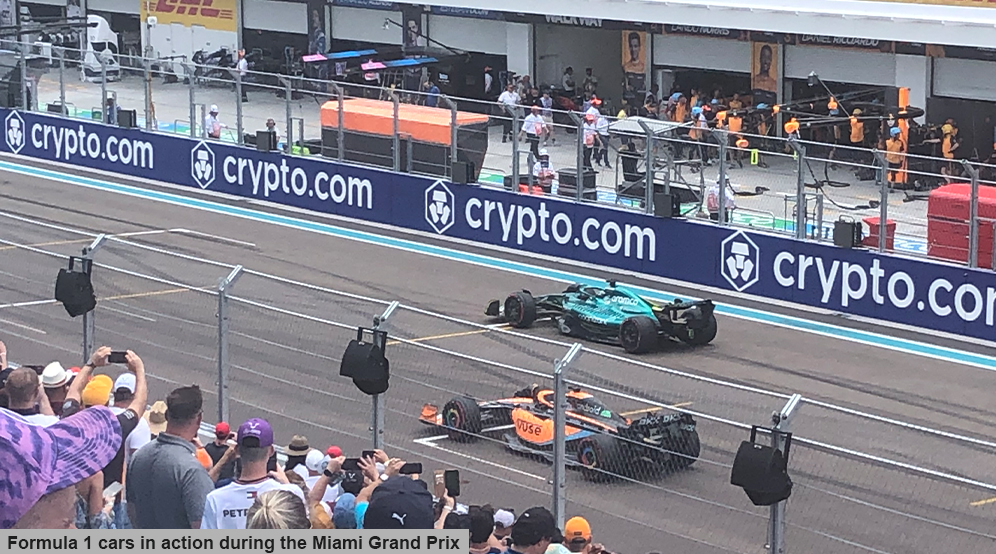

Formula 1 Miami Grand Prix

OVERVIEW

The Hard Rock Stadium grounds underwent a successful adaption to host the Formula 1 Miami Grand Prix. The venue extends over three stadium parcels and portions of the Florida Turnpike right-of-way, and includes a 3.3-mile racetrack with 19 turns and three straightaways where cars reach speeds of up to 210 MPH. It also provides a pit paddock building that can accommodate up to 93,000 spectators, with grandstands, fan amenities, and two levels of VIP suites.

Langan’s site/civil engineers helped integrate the racetrack by providing detailed grading from the edge of the track to meet existing elevations. The team also provided stormwater management design, utility relocations, water and sewer main design, permitting, and construction support.

Accuracy was imperative for the success of this project. Existing conditions for the 240-acre site required positional accuracy within one centimeter. We combined mobile mapping (LiDAR), terrestrial LiDAR, and traditional surveying methodologies to provide the most efficient survey for the racetrack. Approximately 350 survey controls were required, and we obtained information on over 1,000 utility structures. Our surveyors also worked closely with the site/civil team, conducting an initial topographic survey and DTM to support the site/civil design.

Langan’s geotechnical team performed a comprehensive geotechnical engineering study along the proposed racetrack alignment, including subsurface investigations, drainage studies, and pavement evaluation. We also provided delineation of unsuitable materials, site preparation recommendations, and foundation recommendations for the grandstands and pit paddock building.

During construction, Langan provided a precise survey of the actual track surface, which was used to generate a final digital terrain model of the track. We utilized mobile mapping (LiDAR) to develop this deliverable; it provided data along the entire track and created a point cloud with over two billion points and contour deviation of less than five millimeters. We uploaded all of this information directly to a micro-milling machine guidance control system for final paving of the course.