Langan Environmental Qualifications

Langan works with project teams to provide leading edge, focused, streamlined investigations and risk-based remediation. We excel in promoting and gaining regulatory acceptance of risk based strategies to obtain cost effective site closures. Langan possesses expertise in a wide variety of projects including state Voluntary Programs, Brownfields, RCRA, State and Federal Superfund, Manufactured Gas Plants (MGP) and Storage Tank programs.

Piney Branch Shopping Center

Confidential Site – Baltimore

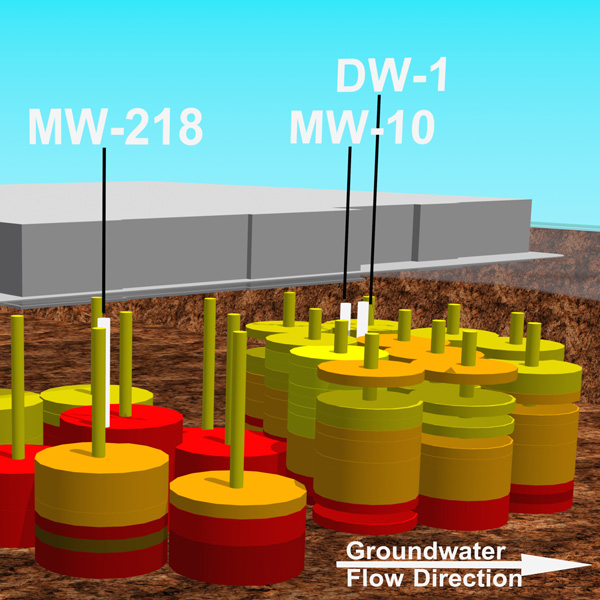

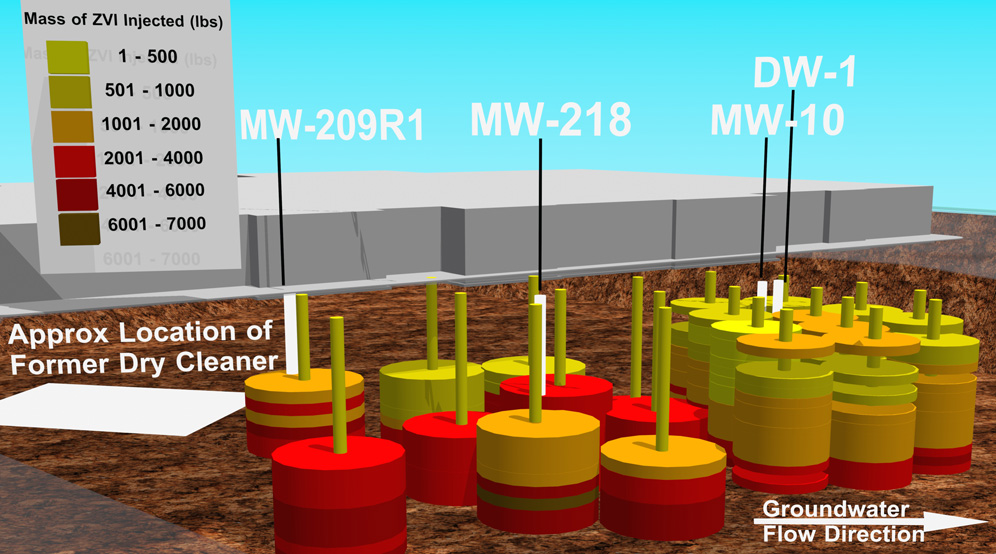

Pneumatic Fracturing & Injection of Zero-Valent Iron

Location

Randallstown, MD

535 4th Avenue

Location

Brooklyn, NY

Client

Slate Property Group

1535 Bedford Avenue

Location

Brooklyn, NY

Client

Adam America Real Estate

Services

Geotechnical

Environmental

Architect

Issac & Stern Architects

Full Scale Groundwater Remediation System

Because of the extent and nature of the contamination, new building, site-access restrictions, and nearby receptor concerns associated with the highly urban location of the site, the remedial strategy required carefully formulating a remediation technology, health and safety precautions, and design remedy. The integrated remedial approach consisted of a MPE system, a SVE system, and an air sparge system to address both the No. 4 Fuel Oil and gasoline free product impacts simultaneously. In addition, an active vapor mitigation system was designed to mitigate any resulting vapor intrusion issues. Due to the planned residential use of the new building, all treatment wells, manifold, and instrumentation associated with the remediation and vapor mitigation systems were installed below the structural slab of the building.

Hybrid Landfill Gas Mitigation System Implementation

The LFG mitigation system consisted of a vapor barrier and hybrid LFG venting system installed under the extents of the building complex floor slab. The innovative hybrid system design allows for both passive and active, if needed, venting of LFG generated below the slab of the building complex.

In-Situ Chemical Oxidation

Langan performed a bench-scale treatability study that evaluated three different persulfate activation methods: 1) sodium hydroxide activation, 2) quick lime activation, and 3) iron activation. Iron did not need to be added because of abundant the iron mineral magnetite in the site soil. Based on the treatability test results, soil mixing with iron activation using natural iron and additional iron-EDTA was selected for field implementation.

Under Langan oversight, Viasant completed ISCO remedial implementation consisting of blending approximately 150,000 pounds of sodium persulfate, 110,000 pounds of 25% sodium hydroxide, and 1,000 pounds of iron-EDTA into a 7,000-cubic-yard mixing volume over 13,500 square feet. A dual-axis mixing head enabled even and precise mixing and dosing. The clean overburden was removed before mixing and backfilled after mixing. Before final backfilling, the top 1-foot mixing zone was stabilized with cement to increase the soil strength.

The Langan/Viasant team implemented innovative risk management procedures to ensure success. Field treatability tests were conducted on-site daily to confirm the dosages buffer reagent (sodium hydroxide), because the rapid activation and reaction drove the soil pH lower during mixing. Samples were taken from each cell upon mixing completion, and their persulfate residual concentrations, pH, and iron levels were measured and evaluated against performance criteria immediately. The mixing cells that failed the criteria were remixed till performance criteria were met.

The performance monitoring results showed that target contaminants were reduced significantly without rebound after one year. Adequate dosage and complete contact results in the successful reduction.